Condensate Pipe Sizing per Ton: A Comprehensive Guide

When it comes to condensate pipe sizing, understanding the process and factors involved is crucial for ensuring efficient and effective system performance. In this article, we will delve into the intricacies of sizing condensate pipes based on tonnage, providing you with a detailed and multi-dimensional overview.

Understanding Condensate

Condensate is the water that forms when steam or hot water cools down and turns back into its liquid state. It is a byproduct of many industrial processes and heating systems. Properly managing condensate is essential for maintaining system efficiency and preventing damage to equipment.

Why Size Condensate Pipes per Ton?

Sizing condensate pipes based on tonnage ensures that the system can handle the expected amount of condensate without causing backups or overflows. It also helps in optimizing the flow rate and pressure, leading to improved overall performance.

Factors Affecting Condensate Pipe Sizing

Several factors influence the sizing of condensate pipes, including:

-

Steam or hot water flow rate

-

Temperature difference between steam and condensate

-

System pressure

-

Pipe material and thickness

-

Gravity and elevation changes

Calculating Condensate Pipe Sizing

Calculating the appropriate size for condensate pipes involves several steps:

-

Determine the steam or hot water flow rate in pounds per hour (lb/h) or gallons per minute (gpm).

-

Calculate the condensate flow rate based on the steam or hot water flow rate and the latent heat of vaporization.

-

Consider the temperature difference between steam and condensate.

-

Calculate the pressure drop across the pipe based on the system pressure and pipe length.

-

Select the appropriate pipe size based on the condensate flow rate, temperature difference, and pressure drop.

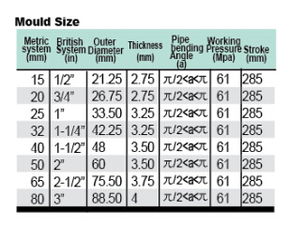

Table: Condensate Pipe Sizing Chart

| Condensate Flow Rate (lb/h) | Pipe Size (inches) |

|---|---|

| 100 | 1/2 |

| 200 | 3/4 |

| 300 | 1 |

| 400 | 1 1/4 |

| 500 | 1 1/2 |

| 600 | 2 |

| 700 | 2 1/2 |

| 800 | 3 |

| 900 | 3 1/2 |

| 1000 | 4 |

Considerations for Pipe Material and Thickness

The choice of pipe material and thickness is crucial for ensuring the longevity and reliability of the condensate system. Common materials include copper, steel, and plastic. The thickness of the pipe should be selected based on the system pressure and the expected temperature variations.

Gravity and Elevation Changes

Gravity and elevation changes can significantly impact the flow of condensate. It is essential to consider these factors when sizing condensate pipes. Proper slope and elevation changes can help in preventing backups and ensuring smooth flow.

Conclusion

Condensate pipe sizing per ton is a critical aspect of maintaining an efficient and effective heating system. By understanding the factors involved and following the appropriate sizing guidelines, you can