Understanding Beam Clamp Ton Capacity: A Comprehensive Guide

When it comes to selecting the right beam clamp for your application, one of the most crucial specifications to consider is the ton capacity. This metric determines the maximum load that a beam clamp can safely hold. In this detailed guide, we will delve into the various aspects of beam clamp ton capacity, helping you make an informed decision for your specific needs.

What is Beam Clamp Ton Capacity?

Beam clamp ton capacity refers to the maximum amount of force that a beam clamp can exert on a beam or structure. It is typically measured in tons (or kilonewtons in the metric system) and is an essential factor in ensuring the safety and effectiveness of your application.

Beam clamps are versatile tools used in various industries, including construction, manufacturing, and maintenance. They are designed to securely attach two beams or structures together, providing a strong and stable connection. The ton capacity of a beam clamp is directly related to its ability to withstand the forces exerted on it, making it a critical consideration when choosing the right tool for your project.

Factors Affecting Beam Clamp Ton Capacity

Several factors influence the ton capacity of a beam clamp. Understanding these factors can help you select the appropriate tool for your application:

-

Material: The material used to manufacture the beam clamp plays a significant role in determining its ton capacity. Common materials include steel, aluminum, and stainless steel. Steel clamps generally offer higher ton capacities due to their strength and durability.

-

Design: The design of the beam clamp also affects its ton capacity. Clamps with a larger surface area and more robust construction can typically handle higher loads. Additionally, features like multiple locking points and adjustable jaws can enhance the clamp’s overall performance.

-

Load Distribution: The way the load is distributed across the beam clamp can impact its ton capacity. Clamps with a wide jaw opening and even load distribution can handle higher loads more effectively.

-

Environmental Conditions: The environment in which the beam clamp will be used can also affect its ton capacity. For example, exposure to extreme temperatures, corrosive substances, or harsh conditions may require a more robust and durable clamp.

How to Determine the Required Ton Capacity

Calculating the required ton capacity for your application involves considering the following factors:

-

Load Type: Determine the type of load you will be applying to the beam clamp. This could be a point load, distributed load, or a combination of both.

-

Load Size: Measure the size of the load, such as the weight or force applied to the beam clamp.

-

Beam Material and Size: Consider the material and size of the beams or structures you will be connecting with the beam clamp.

-

Environmental Conditions: Take into account the environmental conditions in which the beam clamp will be used.

Once you have gathered this information, you can consult the manufacturer’s specifications or use online calculators to determine the required ton capacity for your application.

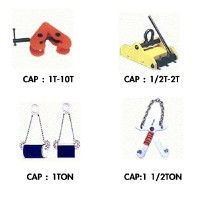

Common Beam Clamp Ton Capacities

Beam clamps come in a wide range of ton capacities, from a few tons to over 100 tons. Here are some common ton capacities you may encounter:

| Beam Clamp Type | Typical Ton Capacity |

|---|---|

| Light-duty beam clamp | Up to 5 tons |

| Mid-duty beam clamp | 5 to 20 tons |

| Heavy-duty beam clamp | 20 to 100 tons |

Choosing the Right Beam Clamp

Selecting the right beam clamp for your application involves considering the ton capacity, as well as other factors such as material, design, and environmental conditions. Here are some tips to help you make the best choice:

-

Assess Your Needs: Determine the specific requirements of your application, including the type of