30 Ton Press Plates: A Comprehensive Guide

When it comes to heavy-duty machinery and industrial applications, the 30 ton press plate is a crucial component that ensures the integrity and functionality of various equipment. Whether you are in the manufacturing industry, automotive sector, or any other field that requires robust machinery, understanding the intricacies of 30 ton press plates is essential. In this article, we will delve into the details of these plates, covering their design, materials, applications, and maintenance. Let’s explore the multifaceted world of 30 ton press plates.

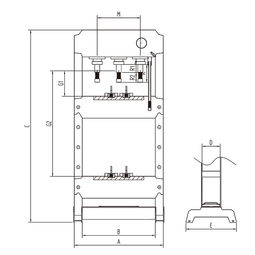

Design and Construction

30 ton press plates are designed to withstand immense pressure and force, making them ideal for heavy-duty applications. These plates are typically constructed using high-quality materials such as steel or alloy steel, which offer excellent strength and durability. The design of these plates is crucial in ensuring that they can bear the weight and pressure they are subjected to.

One of the key aspects of the design is the thickness of the plate. The thickness of a 30 ton press plate can vary depending on the specific application and the manufacturer. Generally, these plates range in thickness from 10mm to 50mm, with the thicker plates being more suitable for heavier loads. The thickness of the plate directly affects its ability to withstand pressure and deformation.

Another important design element is the surface finish. The surface of a 30 ton press plate should be smooth and free from any imperfections, as this ensures that the plate can distribute the pressure evenly across its surface. This even distribution is crucial in preventing localized stress and potential failure points.

Materials Used

The choice of material for 30 ton press plates is critical in determining their overall performance and longevity. High-quality steel or alloy steel is commonly used due to its exceptional strength and resistance to wear and tear. Let’s take a closer look at the materials typically used in the construction of these plates:

| Material | Properties | Applications |

|---|---|---|

| Carbon Steel | High strength, good formability, and cost-effective | Automotive, construction, and general machinery |

| Alloy Steel | Excellent strength, toughness, and resistance to heat and corrosion | Heavy-duty machinery, aerospace, and power generation |

| Stainless Steel | High corrosion resistance, excellent strength, and heat resistance | Chemical processing, food processing, and marine applications |

Applications

30 ton press plates find extensive use in various industries due to their exceptional strength and durability. Some of the most common applications include:

- Automotive industry: Used in the construction of car bodies, engine blocks, and other critical components.

- Construction industry: Employed in the construction of bridges, buildings, and other infrastructure projects.

- Manufacturing industry: Utilized in the production of heavy machinery, presses, and other industrial equipment.

- Aerospace industry: Used in the construction of aircraft components, such as landing gear and engine parts.

- Power generation: Employed in the construction of turbines, generators, and other power plant components.

Maintenance and Care

Proper maintenance and care are essential in ensuring the longevity and performance of 30 ton press plates. Here are some key tips to keep these plates in optimal condition:

- Regular inspection: Conduct regular visual inspections to identify any signs of wear, damage, or deformation.

- Proper storage: Store the plates in a dry, clean, and well-ventilated area to prevent rust and corrosion.

- Regular cleaning: Clean the plates with a suitable solvent or cleaning agent to remove any dirt, grease, or debris.

- Regular maintenance: Schedule periodic maintenance checks to ensure that the plates are functioning correctly and to replace any worn-out or damaged components.

In conclusion, 30 ton press plates are an essential component in various industries, providing the strength and durability required for heavy-duty applications. By understanding their design, materials, applications, and maintenance, you can ensure that these plates continue to perform optimally throughout their lifespan.