80 Ton Hydraulic Cylinder: A Comprehensive Guide

When it comes to heavy-duty machinery and equipment, the 80 ton hydraulic cylinder stands out as a crucial component. This article delves into the intricacies of this powerful cylinder, exploring its design, applications, and the technology behind it.

Understanding the Basics

The 80 ton hydraulic cylinder is a type of hydraulic cylinder designed to exert a force of 80 tons. It is commonly used in various industries, including construction, mining, and manufacturing. The cylinder operates on the principle of hydraulic pressure, where a liquid, typically oil, is used to generate force and movement.

Design and Construction

Designing an 80 ton hydraulic cylinder requires precision and engineering expertise. The cylinder is typically made up of several key components:

-

Barrel: The cylindrical tube that houses the hydraulic fluid and provides the structural integrity of the cylinder.

-

Piston: The sliding component that moves within the barrel, converting hydraulic pressure into linear motion.

-

Seals: Various types of seals are used to prevent fluid leakage and maintain pressure within the cylinder.

-

End caps: These caps secure the ends of the cylinder and provide a mounting surface for the rod and head.

One of the critical aspects of the design is the material used. High-strength steel is commonly used for the barrel and piston due to its durability and resistance to wear. The seals are typically made from materials like polyurethane or PTFE, which offer excellent sealing properties and resistance to high temperatures and chemicals.

Applications

The 80 ton hydraulic cylinder finds applications in various industries, some of which are listed below:

-

Construction: Excavators, cranes, and bulldozers use these cylinders to lift and move heavy loads.

-

Mining: Hydraulic cylinders are used in mining equipment to extract and transport materials.

-

Manufacturing: The cylinders are used in various machinery for assembly, material handling, and processing.

-

Marine: Shipbuilding and offshore drilling platforms utilize these cylinders for lifting and positioning heavy equipment.

Performance and Specifications

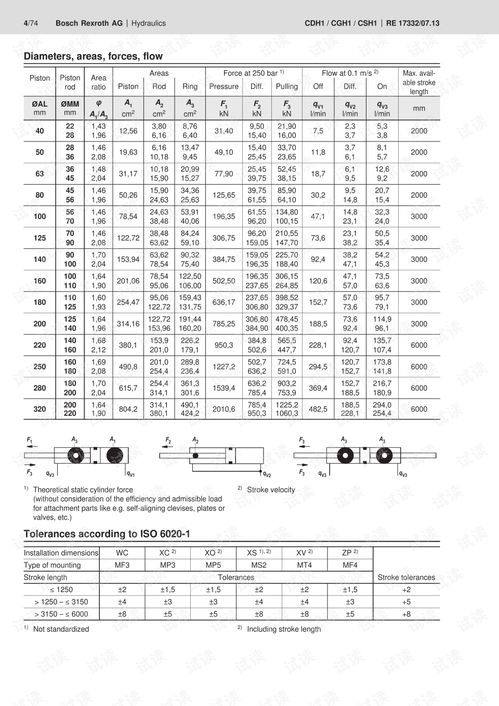

When selecting an 80 ton hydraulic cylinder, it is essential to consider several performance and specification factors:

-

Stroke length: The distance the piston can travel within the barrel. This determines the range of motion for the cylinder.

-

Operating pressure: The maximum pressure the cylinder can withstand without failure. This is typically measured in bars or psi.

-

Speed: The rate at which the cylinder extends or retracts. This is influenced by the flow rate of the hydraulic system.

-

Temperature range: The range of temperatures the cylinder can operate within without damage to its components.

Below is a table showcasing some common specifications for 80 ton hydraulic cylinders:

| Stroke Length (mm) | Operating Pressure (bars) | Speed (mm/s) | Temperature Range (掳C) |

|---|---|---|---|

| 1000 | 280 | 100 | -40 to 100 |

| 1500 | 280 | 80 | -40 to 100 |

| 2000 | 280 | 60 | -40 to 100 |

Maintenance and Care

Proper maintenance and care are essential to ensure the longevity and performance of an 80 ton hydraulic cylinder. Here are some key points to consider:

-

Regular inspections: Check for signs of wear, damage, or leaks in the cylinder and its components.

-

Fluid quality: Ensure the hydraulic fluid is clean and meets the required specifications. Contaminated fluid can lead to premature wear