Understanding Refrigerant Charge Per Ton: A Comprehensive Guide

When it comes to refrigeration systems, one term that often comes up is “refrigerant charge per ton.” This term is crucial for understanding the efficiency and performance of a refrigeration unit. In this article, we will delve into what refrigerant charge per ton means, its importance, and how it affects the overall performance of a refrigeration system.

What is Refrigerant Charge Per Ton?

Refrigerant charge per ton refers to the amount of refrigerant required to cool one ton of refrigerated space. It is a measure of the refrigerant’s capacity to remove heat from the space. The term “ton” in this context is not related to weight but rather to the amount of heat that can be removed. One ton of refrigeration is equivalent to the heat absorbed by one ton of ice melting in 24 hours.

How is Refrigerant Charge Per Ton Calculated?

The calculation of refrigerant charge per ton involves several factors, including the type of refrigeration system, the size of the refrigerated space, and the desired cooling capacity. Here’s a basic formula to calculate the refrigerant charge per ton:

| Refrigerant Charge (lb) | = | Refrigeration Capacity (ton) x 14.2 |

|---|

In this formula, 14.2 is the average refrigerant charge per ton for most refrigeration systems. However, this value can vary depending on the specific system and refrigerant used.

Importance of Refrigerant Charge Per Ton

Understanding the refrigerant charge per ton is essential for several reasons:

-

Efficiency: The correct refrigerant charge ensures optimal system performance and efficiency. An insufficient charge can lead to reduced cooling capacity and increased energy consumption, while an excessive charge can cause compressor damage and reduced efficiency.

-

Environmental Impact: Refrigerants have a significant impact on the environment, particularly in terms of greenhouse gas emissions. Using the correct refrigerant charge helps minimize the environmental impact of the refrigeration system.

-

Cost-Effectiveness: An efficient refrigeration system with the correct refrigerant charge can lead to lower energy bills and reduced maintenance costs.

Factors Affecting Refrigerant Charge Per Ton

Several factors can affect the refrigerant charge per ton, including:

-

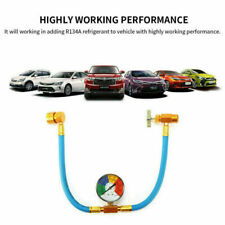

Refrigerant Type: Different refrigerants have different properties and require different charges. For example, R-134a and R-410A have different charge requirements.

-

System Design: The design of the refrigeration system, including the type of compressor, evaporator, and condenser, can affect the refrigerant charge.

-

Operating Conditions: The ambient temperature, the temperature of the refrigerated space, and the load on the system can all impact the refrigerant charge.

How to Determine the Correct Refrigerant Charge

Determining the correct refrigerant charge involves several steps:

-

Consult the Manufacturer’s Specifications: The manufacturer’s specifications for the refrigeration system will provide the recommended refrigerant charge.

-

Use a Refrigerant Charge Calculator: There are various online calculators available that can help determine the correct refrigerant charge based on the system’s specifications.

-

Seek Professional Help: If you are unsure about the correct refrigerant charge, it is best to consult a professional refrigeration technician.

Conclusion

Understanding refrigerant charge per ton is crucial for the efficient and effective operation of a refrigeration system. By ensuring the correct refrigerant charge, you can improve system performance, reduce energy consumption, and minimize environmental impact. Always consult the manufacturer’s specifications or seek professional help to determine the correct refrigerant charge for your system.