100 Ton Hydraulic Press Specifications: A Comprehensive Guide

When it comes to industrial machinery, the 100 ton hydraulic press stands out as a versatile and powerful tool. Whether you’re in the metalworking, forging, or plastic molding industry, understanding the specifications of a 100 ton hydraulic press is crucial for making informed decisions. In this detailed guide, we’ll delve into the various aspects of a 100 ton hydraulic press, including its design, features, and applications.

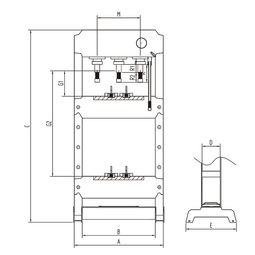

Design and Construction

The design of a 100 ton hydraulic press is a marvel of engineering, combining strength, durability, and efficiency. Typically, these presses are constructed using high-quality steel, which ensures they can withstand the immense pressure and force required for heavy-duty operations. The frame of the press is robust, providing a stable foundation for the hydraulic system and the workpiece.

One of the key components of the design is the hydraulic cylinder. This cylinder is responsible for generating the pressure needed to push the workpiece. In a 100 ton hydraulic press, the cylinder is usually made of chrome-molybdenum steel, which offers excellent strength and resistance to wear. The cylinder is also equipped with seals and rods to prevent any leakage of hydraulic fluid.

Another important aspect of the design is the control system. Modern 100 ton hydraulic presses come with advanced control systems that allow for precise and efficient operation. These systems can be manual, semi-automatic, or fully automatic, depending on the requirements of the user.

Features and Capabilities

100 ton hydraulic presses are known for their impressive features and capabilities. Here are some of the key features that make these presses stand out:

-

High Pressure: As the name suggests, a 100 ton hydraulic press can exert a maximum pressure of 100 tons. This makes it suitable for a wide range of applications, including metalworking, forging, and plastic molding.

-

Large Workspace: These presses typically have a large workspace, allowing for the handling of large and heavy workpieces. The workspace dimensions can vary depending on the specific model, but they usually range from 500mm x 500mm to 1000mm x 1000mm.

-

Multiple Functions: Many 100 ton hydraulic presses come with multiple functions, such as blanking, forming, and deep drawing. This versatility makes them suitable for a variety of applications.

-

Safe Operation: Safety is a top priority in the design of 100 ton hydraulic presses. These presses are equipped with various safety features, such as emergency stop buttons, overload protection, and safety guards.

Applications

100 ton hydraulic presses are widely used in various industries, including:

-

Automotive Industry: These presses are used for the production of automotive parts, such as engine blocks, cylinder heads, and transmission components.

-

Construction Industry: They are used for the manufacturing of steel structures, such as beams, columns, and trusses.

-

Electronics Industry: These presses are used for the production of electronic components, such as connectors and switches.

-

Plastic Molding Industry: They are used for the molding of plastic parts, such as automotive interiors, household appliances, and medical devices.

Technical Specifications

Here is a table showcasing the technical specifications of a typical 100 ton hydraulic press:

| Specification | Value |

|---|---|

| Maximum Pressure | 100 tons |

| Workstation Size | 500mm x 500mm to 1000mm x 1000mm |

| Stroke Length | 100mm to 500mm |

| Power Source | Electric motor |

| Control System | Manual, semi-automatic, or fully automatic |

| Hydraulic Fluid | ISO 46 hydraulic oil |