100 Ton Press Cylinder: A Comprehensive Guide

When it comes to heavy-duty machinery, the 100 ton press cylinder is a piece of equipment that stands out for its robustness and reliability. Whether you’re in the automotive, aerospace, or manufacturing industry, understanding the intricacies of this powerful cylinder is crucial. In this article, we will delve into the various aspects of the 100 ton press cylinder, including its design, applications, and maintenance.

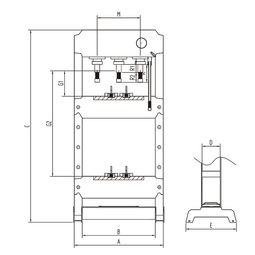

Design and Construction

The 100 ton press cylinder is designed to withstand immense pressure and force, making it an ideal choice for heavy-duty applications. Let’s take a closer look at its design and construction.

| Component | Description |

|---|---|

| Stainless Steel Cylinder Body | The cylinder body is made of high-quality stainless steel, ensuring durability and resistance to corrosion. |

| Seals and Gaskets | Seals and gaskets are used to prevent oil leakage and maintain pressure integrity. |

| High-Pressure Piston Rod | The piston rod is designed to withstand high pressure and is often made of chrome-molybdenum steel. |

| Hydraulic System | The hydraulic system provides the necessary pressure and flow rate for the cylinder to operate efficiently. |

These components work together to ensure that the 100 ton press cylinder can handle the demands of heavy-duty applications.

Applications

The 100 ton press cylinder is widely used in various industries due to its exceptional strength and reliability. Here are some of the common applications:

-

Automotive Industry: The cylinder is used for pressing, bending, and forming metal components in the automotive manufacturing process.

-

Aerospace Industry: In the aerospace industry, the 100 ton press cylinder is used for the assembly and testing of aircraft components.

-

Manufacturing Industry: The cylinder is used for metal stamping, forging, and other heavy-duty manufacturing processes.

-

Construction Industry: The 100 ton press cylinder is used for the assembly and installation of heavy machinery and equipment.

Maintenance and Care

Proper maintenance and care are essential to ensure the longevity and performance of the 100 ton press cylinder. Here are some key points to consider:

-

Regular Inspection: Regularly inspect the cylinder for any signs of wear, damage, or leaks.

-

Lubrication: Apply the appropriate lubricant to the cylinder to reduce friction and wear.

-

Hydraulic System: Ensure that the hydraulic system is functioning properly and that the pressure and flow rate are within the specified limits.

-

Training: Ensure that the operators are properly trained on the safe and efficient operation of the cylinder.

Conclusion

The 100 ton press cylinder is a vital piece of equipment for heavy-duty applications. Its robust design, wide range of applications, and proper maintenance make it an essential tool for various industries. By understanding the design, applications, and maintenance of the 100 ton press cylinder, you can ensure that it continues to perform at its best for years to come.