20 Ton Press Gauge: A Comprehensive Guide

Are you in the market for a reliable and precise measuring tool? Look no further than the 20 ton press gauge. This versatile instrument is widely used in various industries for its exceptional accuracy and durability. In this article, we will delve into the details of the 20 ton press gauge, exploring its features, applications, and benefits.

Understanding the 20 Ton Press Gauge

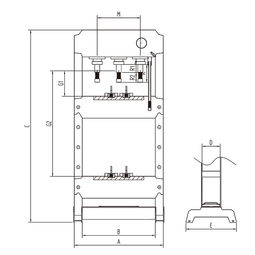

The 20 ton press gauge is a type of force gauge designed to measure the force required to deform a material under compression. It is capable of measuring forces up to 20 tons, making it suitable for a wide range of applications. The gauge typically consists of a load cell, a display unit, and a mechanical or digital interface.

One of the key features of the 20 ton press gauge is its high precision. The gauge is designed to provide accurate measurements within a tight tolerance, ensuring reliable results. This precision is crucial in industries such as automotive, aerospace, and manufacturing, where even the smallest variations in force can have significant implications.

Features of the 20 Ton Press Gauge

Here are some of the key features that make the 20 ton press gauge a popular choice among professionals:

- High Capacity: The gauge can measure forces up to 20 tons, making it suitable for a wide range of applications.

- Precision: The gauge offers high precision measurements, ensuring reliable results.

- Robust Construction: The gauge is built to withstand harsh conditions, ensuring durability and longevity.

- Digital Display: Many models come with a digital display, providing easy-to-read measurements.

- Calibration: The gauge can be easily calibrated to ensure accurate measurements over time.

Applications of the 20 Ton Press Gauge

The 20 ton press gauge is used in various industries for a wide range of applications. Here are some of the most common uses:

- Automotive Industry: The gauge is used to test the strength and durability of automotive components, such as suspension systems, brakes, and exhaust systems.

- Aerospace Industry: The gauge is used to test the strength and integrity of aerospace components, such as landing gears, wings, and fuselages.

- Manufacturing Industry: The gauge is used to test the strength and quality of materials used in manufacturing processes, such as metals, plastics, and composites.

- Research and Development: The gauge is used in research and development to test the properties of new materials and products.

Benefits of Using the 20 Ton Press Gauge

Using a 20 ton press gauge offers several benefits, including:

- Improved Quality Control: The gauge helps ensure that products meet the required quality standards.

- Enhanced Safety: The gauge helps identify potential issues with materials and components before they cause accidents or failures.

- Cost Savings: By identifying and addressing issues early on, the gauge can help reduce costs associated with repairs and replacements.

- Increased Efficiency: The gauge allows for quick and accurate measurements, improving overall efficiency in the workplace.

Choosing the Right 20 Ton Press Gauge

When selecting a 20 ton press gauge, it is important to consider several factors to ensure that you choose the right instrument for your needs:

- Capacity: Make sure the gauge has the capacity to measure the forces you need to test.

- Precision: Choose a gauge with the required level of precision for your application.

- Features: Look for features that will make the gauge easier to use and more suitable for your specific needs.

- Brand: Consider the reputation and reliability of the brand when making your purchase.

Conclusion

The 20 ton press gauge is a valuable tool for professionals in various industries. Its high precision, durability, and versatility make it an excellent choice for measuring forces up to 20 tons. By understanding the features, applications, and benefits of the 20 ton press gauge, you can make an informed decision when selecting the right instrument for your needs.