20 Ton Press Parts: A Comprehensive Guide

When it comes to manufacturing and engineering, the 20 ton press is a crucial piece of equipment. Whether you’re in the automotive, aerospace, or metalworking industry, understanding the various parts that make up a 20 ton press is essential. In this detailed guide, we’ll explore the different components, their functions, and how they work together to ensure optimal performance.

Understanding the Basics

The 20 ton press is a type of mechanical press that is designed to apply a force of 20 tons to a workpiece. These presses are commonly used in metalworking, forging, and stamping applications. The main components of a 20 ton press include the frame, bed, ram, and hydraulic system.

| Component | Description |

|---|---|

| Frame | The frame is the main structure that supports the entire press. It provides stability and rigidity, ensuring that the press operates smoothly and safely. |

| Bed | The bed is the flat surface on which the workpiece is placed. It is designed to be durable and wear-resistant, allowing for repeated use without damage. |

| Ram | The ram is the moving part of the press that applies force to the workpiece. It is connected to the hydraulic system and moves up and down, pushing the workpiece against the die. |

| Hydraulic System | The hydraulic system is responsible for generating the force required to move the ram. It consists of a pump, motor, valves, and cylinders. |

The Frame: The Backbone of the Press

The frame is the largest and most critical component of a 20 ton press. It is typically made of high-strength steel and is designed to withstand the immense forces generated during operation. The frame provides support for the bed, ram, and hydraulic system, ensuring that the press remains stable and secure.

Frames can vary in design, with some featuring a box-type construction for added rigidity. Others may have a C-channel or I-beam design, depending on the specific requirements of the application. The frame is also equipped with mounting points for the hydraulic system and other accessories, such as safety guards and control panels.

The Bed: The Foundation for Precision

The bed is the flat surface on which the workpiece is placed. It is crucial for ensuring that the workpiece is properly aligned and supported during the pressing process. Beds are typically made of high-quality steel, which is heat-treated to improve its hardness and wear resistance.

Beds come in various sizes and configurations, depending on the type of workpiece being processed. Some beds are equipped with T-slots for mounting fixtures and jigs, while others have a smooth surface for direct placement of the workpiece. The bed’s design and material play a significant role in the overall precision and quality of the finished product.

The Ram: The Force Behind the Press

The ram is the moving part of the 20 ton press that applies force to the workpiece. It is connected to the hydraulic system and moves up and down, pushing the workpiece against the die. The ram’s design and material are critical factors in determining the press’s performance and lifespan.

Rams are typically made of high-strength steel and are heat-treated to improve their hardness and durability. The ram’s size and shape are determined by the specific application and the force required to deform the workpiece. Some rams are equipped with features such as cushioning or shock-absorbing systems to reduce vibration and extend the press’s lifespan.

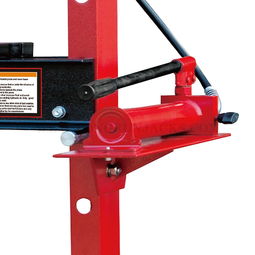

The Hydraulic System: The Heart of the Press

The hydraulic system is responsible for generating the force required to move the ram. It consists of a pump, motor, valves, and cylinders. The pump and motor work together to circulate hydraulic fluid, which is then used to power the ram and other components of the press.

Hydraulic systems can vary in design, with some featuring a single pump and others using a dual-pump configuration for increased efficiency. The valves control the flow of hydraulic fluid, ensuring that the press operates smoothly and safely. Cylinders are used to convert the hydraulic fluid’s pressure into mechanical force, allowing the ram to move up and down.

Conclusion

In conclusion, the 20 ton