20 Ton Press Plans: A Comprehensive Guide

Are you looking to delve into the world of 20 ton press plans? Whether you’re an engineer, a hobbyist, or simply curious about the intricacies of these powerful machines, this guide is tailored to provide you with a detailed and multi-dimensional overview. From their design and components to their applications and safety measures, we’ll explore everything you need to know about 20 ton press plans.

Understanding the Basics

Before we dive into the specifics, let’s establish a clear understanding of what a 20 ton press is. A 20 ton press, also known as a hydraulic press, is a mechanical device used to apply compressive force to various materials. It is commonly used in manufacturing, metalworking, and other industrial applications.

Before we dive into the specifics, let’s establish a clear understanding of what a 20 ton press is. A 20 ton press, also known as a hydraulic press, is a mechanical device used to apply compressive force to various materials. It is commonly used in manufacturing, metalworking, and other industrial applications.

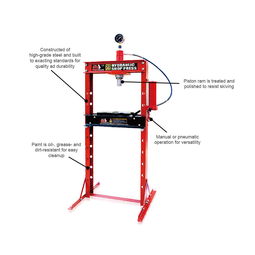

A 20 ton press operates on the principle of hydraulics, where a fluid (usually oil) is used to transfer force from one point to another. The press consists of several key components, including the hydraulic cylinder, ram, and control system.

Design and Components

The design of a 20 ton press is a marvel of engineering, combining strength, precision, and efficiency. Let’s take a closer look at its key components:

The design of a 20 ton press is a marvel of engineering, combining strength, precision, and efficiency. Let’s take a closer look at its key components:

- Hydraulic Cylinder: This is the heart of the press, responsible for generating the compressive force. It consists of a cylinder, piston, and seals, all designed to withstand high pressure and ensure smooth operation.

- Ram: The ram is the part of the press that moves up and down, applying force to the workpiece. It is typically made of high-strength steel and is equipped with various attachments to accommodate different types of work.

- Control System: The control system allows the operator to regulate the press’s operation, including the speed, force, and position of the ram. Modern presses often feature advanced control systems with programmable logic controllers (PLCs) for enhanced precision and safety.

Applications

20 ton presses are versatile machines with a wide range of applications. Here are some of the most common uses:

20 ton presses are versatile machines with a wide range of applications. Here are some of the most common uses:

- Forging: The high force generated by a 20 ton press is ideal for forging metal parts, such as bolts, nuts, and other components.

- Stamping: These presses are often used for stamping operations, where metal sheets are deformed into various shapes and sizes.

- Die Cutting: Die cutting involves using a 20 ton press to cut out shapes from metal sheets or other materials.

- Pressing: The press can be used to press different materials together, creating bonds or forming new shapes.

Safety Measures

Safety is a top priority when working with 20 ton presses. Here are some essential safety measures to consider:

- Training: Operators should receive proper training on how to safely operate the press, including the use of safety guards and emergency stop mechanisms.

- Regular Maintenance: Regular maintenance is crucial to ensure the press operates safely and efficiently. This includes checking the hydraulic system, control system, and other components for wear and tear.

- Safety Guards: Safety guards should be installed to protect operators from moving parts and potential hazards.

- Emergency Stop: An emergency stop button should be readily accessible to quickly shut down the press in case of an emergency.

Choosing the Right 20 Ton Press Plan

When selecting a 20 ton press plan, it’s essential to consider several factors to ensure you get the right machine for your needs:

- Capacity: Ensure the press has the appropriate capacity for your intended applications.

- Speed: The speed of the press’s ram is an important factor, especially for high-volume production.

- Control System: Choose a press with a control system that meets your requirements, whether it’s manual, semi-automatic, or fully automatic.

- Brand and Manufacturer: Research reputable brands and manufacturers with a proven track record of producing high-quality presses.

Conclusion

In conclusion, a 20 ton press is a powerful and versatile machine with numerous applications in various industries. By understanding its design, components, applications, and safety measures, you can make an informed decision when selecting a 20 ton press plan. Always prioritize safety and choose a reputable manufacturer