20 Ton Press Uses: A Comprehensive Guide

Are you considering investing in a 20 ton press for your business? Understanding the various uses of such a machine is crucial to make an informed decision. In this article, we will delve into the different applications of a 20 ton press, helping you explore its potential benefits and limitations.

What is a 20 Ton Press?

A 20 ton press is a heavy-duty machine designed to apply significant force to various materials. It is commonly used in industries such as metalworking, manufacturing, and construction. The machine can exert a force of 20 tons, which is equivalent to 20 metric tons or 44,092 pounds.

Applications of a 20 Ton Press

1. Metalworking

One of the primary uses of a 20 ton press is in metalworking. These presses are ideal for bending, forming, and shaping metal sheets, plates, and bars. They can handle materials like steel, aluminum, and brass, making them versatile for various metalworking applications.

2. Manufacturing

In the manufacturing sector, a 20 ton press can be used for various purposes, such as assembling components, stamping, and forging. The high force exerted by the press ensures precision and durability in the final product.

3. Construction

Construction companies can benefit from a 20 ton press for tasks like breaking concrete, asphalt, or other hard materials. The press’s powerful force makes it an excellent tool for demolition and excavation work.

4. Automotive Industry

The automotive industry relies on 20 ton presses for tasks like stamping, bending, and forming metal parts. These presses are essential for manufacturing car bodies, engine components, and other automotive parts.

5. Aerospace Industry

In the aerospace sector, a 20 ton press is used for manufacturing lightweight, high-strength components. These presses help in shaping and forming materials like titanium and aluminum, which are crucial for aerospace applications.

Types of 20 Ton Presses

1. Mechanical Presses

Mechanical presses are the most common type of 20 ton press. They use a flywheel and a crank mechanism to generate force. These presses are known for their reliability and durability.

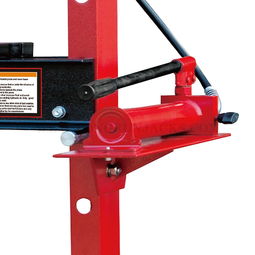

2. Hydraulic Presses

Hydraulic presses use hydraulic fluid to generate force. They are known for their high force output and are suitable for heavy-duty applications. Hydraulic presses are also more energy-efficient than mechanical presses.

3. Pneumatic Presses

Pneumatic presses use compressed air to generate force. They are suitable for lighter-duty applications and are known for their fast cycle times and low maintenance requirements.

Benefits of Using a 20 Ton Press

1. Increased Productivity

By automating various processes, a 20 ton press can significantly increase productivity in your business. The high force output allows for faster and more efficient operations.

2. Improved Precision

The precision and consistency offered by a 20 ton press ensure high-quality products. The machine’s ability to apply uniform force across the material ensures consistent results.

3. Cost-Effective

Investing in a 20 ton press can be cost-effective in the long run. The machine’s ability to handle various materials and applications reduces the need for multiple machines, thereby saving on space and maintenance costs.

Considerations Before Buying a 20 Ton Press

1. Space Requirements

Ensure that your workspace can accommodate the size and weight of a 20 ton press. Consider the available floor space, ceiling height, and electrical requirements.

2. Power Source

Check the power requirements of the press and ensure that your electrical system can support it. Consider the voltage, current, and frequency requirements.

3. Safety Features

Look for a press with advanced safety features, such as emergency stop buttons, safety guards, and overload protection. These features are crucial for ensuring the safety of your workers.

4. Maintenance and Service

Consider the maintenance and service requirements of the press. Choose a reputable manufacturer that offers reliable customer support and spare parts.

Conclusion

A 20 ton press is a versatile and powerful machine with numerous applications across various industries. By understanding its uses, benefits, and considerations, you can make an informed decision when investing in one for your business. Remember to choose a reputable manufacturer and ensure that your workspace can accommodate the machine’s requirements