3 Ton Jack Parts: A Comprehensive Guide

When it comes to heavy-duty lifting equipment, the 3 ton jack is a staple. Whether you’re a professional mechanic or a DIY enthusiast, understanding the various parts that make up a 3 ton jack is crucial for its proper use and maintenance. In this detailed guide, we’ll delve into the different components, their functions, and how they contribute to the overall performance of your jack.

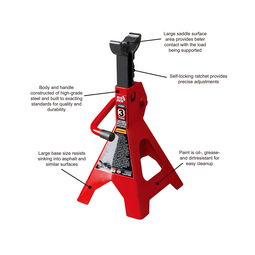

Frame and Base

The frame and base of a 3 ton jack are its foundation. They provide the structural integrity needed to support the weight of the vehicle and the lifting force. The frame is typically made of high-quality steel, ensuring durability and strength. The base, on the other hand, is designed to distribute the weight evenly and provide stability during the lifting process.

Lifting Mechanism

The heart of a 3 ton jack is its lifting mechanism. This component is responsible for raising and lowering the vehicle. There are several types of lifting mechanisms, including:

- Hydraulic Jack: This is the most common type of lifting mechanism. It uses hydraulic pressure to lift the vehicle. The hydraulic system consists of a pump, reservoir, and hydraulic cylinder. The pump generates pressure, which is then transferred to the cylinder, lifting the vehicle.

- Pneumatic Jack: Similar to a hydraulic jack, a pneumatic jack uses compressed air to generate lifting force. It is often used in situations where a hydraulic jack is not available.

- Manual Jack: A manual jack uses a lever or screw mechanism to lift the vehicle. While less common in 3 ton jacks, manual jacks are still used in some applications.

Hydraulic System

For hydraulic jacks, the hydraulic system is a critical component. It includes the following parts:

- Pump: The pump generates hydraulic pressure by moving fluid through the system. It is typically driven by an electric motor or a hand-crank.

- Reservoir: The reservoir stores hydraulic fluid and helps to maintain pressure in the system. It also acts as a heat sink, dissipating heat generated during the lifting process.

- Hydraulic Cylinder: The hydraulic cylinder is responsible for converting hydraulic pressure into lifting force. It is connected to the lifting arm and moves up and down as the fluid is pumped through the system.

Lifting Arm and Ram

The lifting arm and ram are the components that actually lift the vehicle. The lifting arm is connected to the frame and extends out to the vehicle’s undercarriage. The ram is attached to the lifting arm and moves up and down, lifting the vehicle as the hydraulic pressure is applied.

- Lifting Arm: The lifting arm is designed to fit the specific make and model of your vehicle. It must be securely attached to the frame and the ram to ensure proper lifting.

- Ram: The ram is the part that actually contacts the vehicle’s undercarriage. It must be made of a durable material, such as steel, to withstand the pressure and weight of the vehicle.

Control Valves and Fittings

Control valves and fittings are essential for regulating the flow of hydraulic fluid and ensuring the safe operation of the jack. The following components are commonly found in a 3 ton jack:

- Check Valve: The check valve prevents fluid from flowing back into the reservoir when the pump is turned off.

- Relief Valve: The relief valve releases excess pressure in the system, preventing damage to the pump and other components.

- Pressure Gauge: The pressure gauge provides a visual indication of the hydraulic pressure in the system.

- Quick Coupler: The quick coupler allows for easy connection and disconnection of the hydraulic lines.

Wheels and Handles

The wheels and handles of a 3 ton jack are designed for easy maneuverability and portability. The following components are typically included:

- Wheels: The wheels must be sturdy and capable of supporting the weight of the jack and the vehicle being lifted.

- Handles: The handles provide a comfortable grip for lifting and moving the jack.