10 Ton Hydraulic Press: A Comprehensive Guide

Are you looking to invest in a hydraulic press for your workshop or industrial setting? If so, a 10 ton hydraulic press is a versatile and powerful option to consider. In this detailed guide, we will explore the various aspects of a 10 ton hydraulic press, including its features, benefits, applications, and maintenance tips.

Understanding the Basics

A hydraulic press is a mechanical device that uses the power of hydraulic fluid to generate a high force. The 10 ton hydraulic press, as the name suggests, can exert a force of 10 tons (or 10,000 kilograms) on its workpiece. This makes it suitable for a wide range of applications, from metalworking to plastic molding.

Here’s a brief overview of the key components of a 10 ton hydraulic press:

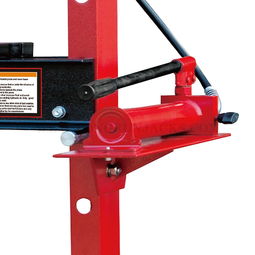

- Pump: The heart of the hydraulic press, the pump delivers hydraulic fluid to the cylinders.

- Cylinder: The cylinder contains the hydraulic fluid and converts the fluid’s pressure into mechanical force.

- Valves: Valves control the flow of hydraulic fluid, ensuring that the press operates efficiently.

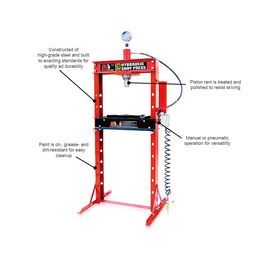

- Frame: The frame provides structural support and stability to the press.

Features of a 10 Ton Hydraulic Press

When choosing a 10 ton hydraulic press, there are several features to consider:

- Frame Material: Look for a press with a sturdy frame made of high-quality steel for durability and longevity.

- Stroke Length: The stroke length determines the maximum depth the press can travel. Ensure it meets your specific application requirements.

- Speed: The press’s speed should be adjustable to accommodate different tasks and materials.

- Control Panel: A user-friendly control panel with various settings and safety features is essential for efficient operation.

- Hydraulic System: A reliable and efficient hydraulic system ensures consistent performance and reduced maintenance.

Benefits of a 10 Ton Hydraulic Press

Investing in a 10 ton hydraulic press offers several benefits:

- Increased Productivity: The press can handle heavy-duty tasks, allowing you to complete more work in less time.

- Improved Quality: The consistent force and precision of the press ensure high-quality results.

- Cost-Effective: A 10 ton hydraulic press can be a cost-effective solution for your workshop or industrial needs.

- Versatility: The press can be used for various applications, from metalworking to plastic molding.

Applications of a 10 Ton Hydraulic Press

A 10 ton hydraulic press can be used in various industries and applications, including:

- Automotive: For repairing and manufacturing automotive parts, such as brakes and suspension components.

- Construction: For bending and shaping metal materials used in construction projects.

- Plastic Molding: For molding plastic parts used in various industries, such as electronics and automotive.

- Machine Shops: For metalworking tasks, such as forging, stamping, and bending.

Maintenance Tips for a 10 Ton Hydraulic Press

Proper maintenance is crucial for ensuring the longevity and performance of your 10 ton hydraulic press. Here are some essential maintenance tips:

- Regular Inspections: Conduct regular inspections of the press to identify any potential issues early on.

- Hydraulic Fluid: Change the hydraulic fluid at recommended intervals to maintain its performance and prevent contamination.

- Seals and Gaskets: Check and replace worn-out seals and gaskets to prevent leaks and maintain pressure.

- Valves and Pumps: Ensure that the valves and pumps are functioning correctly and replace any faulty components.

- Training: Ensure that your operators are properly trained on the safe and efficient operation of the press.

By following these maintenance tips, you can extend the lifespan of your 10 ton hydraulic press and ensure its optimal performance.