Overhead Crane 5 Ton: A Comprehensive Guide

Are you in the market for a reliable overhead crane that can handle up to 5 tons? Look no further! In this detailed guide, we will explore the various aspects of a 5-ton overhead crane, including its design, features, applications, and maintenance. Whether you are a business owner, engineer, or simply curious about these heavy-duty lifting devices, this article will provide you with all the information you need.

Design and Construction

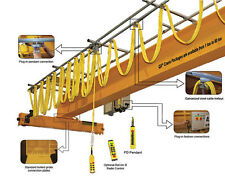

The design of a 5-ton overhead crane is a marvel of engineering, combining strength, durability, and efficiency. These cranes are typically constructed using high-quality steel, which ensures they can withstand the rigors of heavy lifting. The main components of a 5-ton overhead crane include the bridge, trolley, hoist, and electrical system.

| Component | Description |

|---|---|

| Bridge | The horizontal beam that runs along the runway, supporting the trolley and hoist. |

| Trolley | The carriage that moves along the bridge, carrying the hoist and lifting the load. |

| Hoist | The lifting mechanism that raises and lowers the load. |

| Electrical System | The system that powers the crane, including motors, controllers, and wiring. |

One of the key features of a 5-ton overhead crane is its ability to handle heavy loads with precision. The crane’s design ensures that the load is evenly distributed, reducing the risk of accidents and damage to the equipment.

Features

When selecting a 5-ton overhead crane, it’s important to consider its features to ensure it meets your specific needs. Here are some of the most important features to look for:

- Load Capacity: As the name suggests, a 5-ton overhead crane can handle loads up to 5 tons. However, it’s important to choose a crane with a slightly higher capacity to account for any unexpected increases in load.

- Span Length: The span length is the distance between the two ends of the bridge. This determines how far the crane can reach. Choose a span length that meets your lifting requirements.

- Hoist Speed: The hoist speed is the rate at which the crane can raise and lower the load. Faster hoist speeds can increase productivity, but they may also require more power.

- Control System: The control system allows you to operate the crane safely and efficiently. Look for a system that is easy to use and offers a range of control options, such as push-button, pendant, or radio control.

- Electrical System: Ensure the crane’s electrical system is reliable and can handle the power requirements of your application.

Applications

5-ton overhead cranes are versatile lifting devices that can be used in a wide range of industries and applications. Some of the most common uses include:

- Manufacturing: These cranes are ideal for lifting heavy components and materials in manufacturing plants.

- Construction: They can be used to lift materials and equipment on construction sites.

- Warehouse: Overhead cranes are essential for moving heavy loads in warehouses and distribution centers.

- Automotive: They are used in automotive plants for lifting vehicles and parts.

Maintenance

Proper maintenance is crucial for ensuring the longevity and safety of your 5-ton overhead crane. Here are some key maintenance tips:

- Regular Inspections: Conduct regular inspections of the crane’s components, including the bridge, trolley, hoist, and electrical system.

- Lubrication: Regularly lubricate the crane’s moving parts to reduce wear and tear.

- Replacement Parts: Replace worn-out or damaged parts promptly to prevent accidents.

- Training: Ensure that all operators are properly trained on how to safely operate the