Wire Rope Sling 25 Ton: A Comprehensive Guide

Are you in the market for a reliable lifting solution? Look no further than the wire rope sling 25 ton. This versatile piece of equipment is designed to handle heavy loads with precision and safety. In this detailed guide, we will explore the various aspects of the wire rope sling 25 ton, including its construction, features, applications, and maintenance. Whether you are a professional in the lifting industry or a DIY enthusiast, this article will provide you with all the information you need to make an informed decision.

Understanding Wire Rope Sling 25 Ton

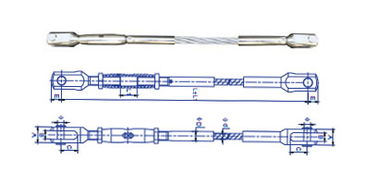

The wire rope sling 25 ton is a type of lifting device made from high-quality steel wire ropes. It is designed to provide a safe and efficient means of lifting heavy loads. The 25-ton capacity indicates that this sling can handle loads up to 25 metric tons (25,000 kilograms). Let’s delve deeper into its construction and components.

| Component | Description |

|---|---|

| Steel Wire Ropes | High-tensile steel wires are twisted together to form a strong and flexible rope. These ropes are the backbone of the sling and provide the necessary strength to lift heavy loads. |

| Eye Splices | Eye splices are used to create loops at both ends of the sling. They allow for easy attachment to lifting equipment and hooks. |

| End Fittings | End fittings are used to secure the wire ropes together and provide a safe connection point for the sling. |

| Load Testing | Before use, the wire rope sling 25 ton should be load tested to ensure its integrity and safety. This involves applying a load equal to its rated capacity and checking for any signs of damage or wear. |

Features of Wire Rope Sling 25 Ton

Wire rope slings, including the 25-ton variant, offer several advantages over other lifting devices. Here are some of the key features that make them a popular choice:

- High Strength and Durability: The steel wire ropes used in the construction of the sling provide exceptional strength and durability, ensuring that it can handle heavy loads without failure.

- Flexibility: The flexible nature of the wire rope allows for easy maneuverability and reduces the risk of damage to the load being lifted.

- Corrosion Resistance: The steel wire ropes are coated with a protective layer to prevent corrosion, making the sling suitable for use in various environments.

- Longevity: With proper maintenance, a wire rope sling 25 ton can last for many years, providing a cost-effective lifting solution.

Applications of Wire Rope Sling 25 Ton

The wire rope sling 25 ton is a versatile lifting device that can be used in a wide range of industries and applications. Here are some common uses:

- Construction: Lifting heavy materials, such as steel beams and concrete blocks, during construction projects.

- Manufacturing: Moving heavy machinery and components within a manufacturing facility.

- Transportation: Loading and unloading heavy cargo from trucks, ships, and trains.

- Renewable Energy: Installing and maintaining wind turbines and solar panels.

Maintenance and Safety

Proper maintenance and safety practices are crucial when using a wire rope sling 25 ton. Here are some tips to ensure its longevity and prevent accidents:

- Regular Inspection: Inspect the sling for any signs of damage, such as cuts, kinks, or corrosion. If any issues are found, replace the sling immediately.

- Load Testing: Conduct load testing before each use to ensure the sling is in good condition.

- Proper Handling: Always follow the manufacturer’s guidelines for handling and lifting loads with the wire rope sling 25 ton.

- Training: Ensure that all personnel involved in lifting operations are properly trained on the safe